Since its establishment in 1969, the focus of the company has been the development, design and manufacturing of high-quality cooling/heating systems for a variety of applications. Psyctotherm is specialized in HVAC systems, marine/industrial refrigeration, heat exchangers production, installations, repairs, and trading. Its core business areas concern are marine, industrial and commercial applications.

The R&D department was established in 2013 and since then, the average growth of 10-15% per year, allows to invest further on innovation and provide new and upgraded products, with energy efficiency as a top priority. It has received three Seals of Excellence from the E.U. and participates in four more co-funded research programs.

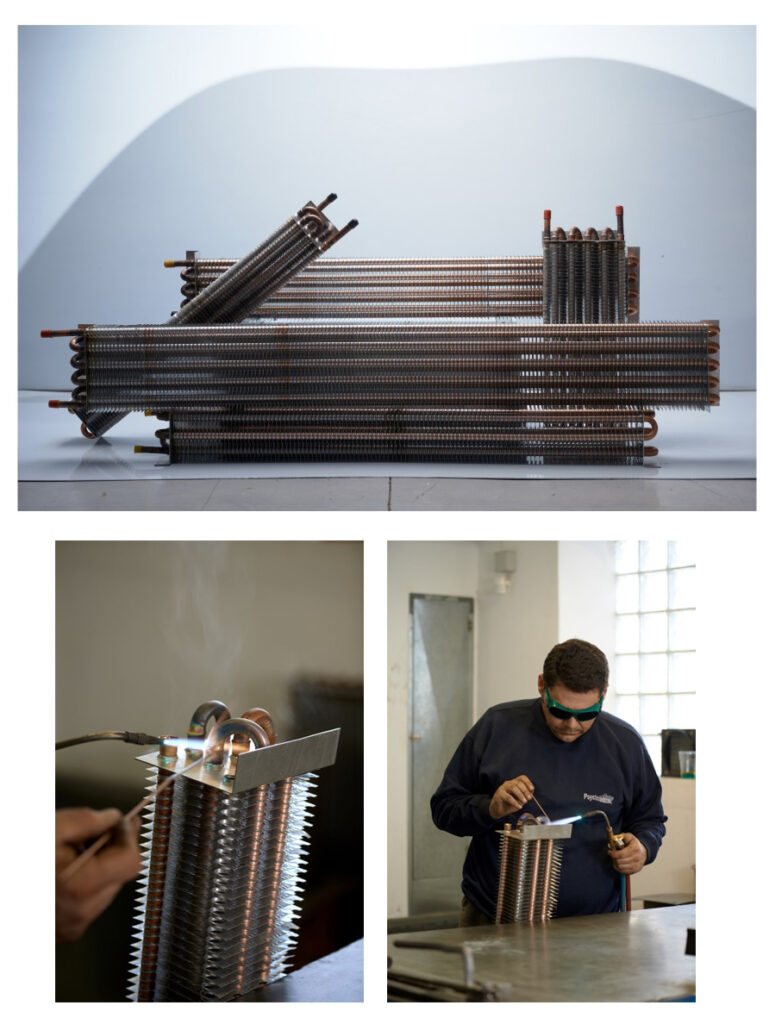

The company operates at its own facilities in Piraeus, Greece, in a total surface area of 1,800 m2, covering activities such as commercial shop, storages, offices, and workshop with modern machinery equipment that has been recently upgraded. Psyctotherm has well-qualified personnel, with long experience and excellent know-how.

We acquired ISO: 9001 and ISO: 14001 certification for quality assurance and ISO 45001 for occupational health and safety. All products are manufactured under relevant EU directives and EN standards, also issuing the certification of conformity for installations in ships and in other business sectors.

Moreover, Psyctotherm is a full member of:

- HEMEXPO association (Hellenic Marine Equipment Manufacturers and Exporters), expanding its customer base and collaborating with other companies in the field to jointly increase their innovation capacity,

- WIMA non-profit association (Worldwide Industrial & Marine Association), a network of certified companies with global reach, offering products and services to the marine sector, with Mr. Ligeros (Manager Director of PSYCTO) being appointed in the Board of Directors of WIMA.

Due to the company’s growth, we initiated the procedure for relocating its manufacturing workshop in a larger proprietary building in Piraeus close to its headquarters. This procedure which will be completed in 2020, also includes large investments on manufacturing machines, a larger warehouse and better handling of all orders. This strategic decision will enable the company to speed-up the production process and gradually double its production capacity, so that to meet the increasing number of orders and sales.