- Ship Transfer System

- Automated plant technology for complex large structures

- Machining centres for profile and pipe production

- Transport systems

- Special machines

- Robotic welding systems

- Shipyard & factory planning

IMG mbH as a system supplier and engineering service provider is one of the leading vendors worldwide of complex plant and transport technology for companies in the shipbuilding, machine construction, structural steelwork and wind energy industries.

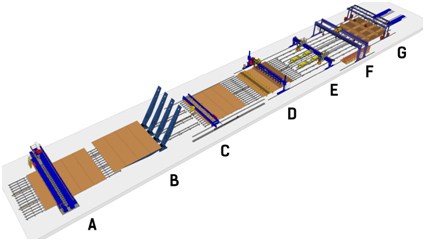

Panel Lines

IMG mbH panel production lines are optimally tailored to the needs of our customers. The panel production lines are made up of stationary and mobile facilities and have varying degrees of automation and mechanisation. The most common application will be panel production in shipbuilding or production lines for bridge panels in the construction sector.Depending on the industry and area of application, we distinguish between the following variants:

Panel lines are important production lines especially in the shipbuilding sector. The biggest effects are achieved with regard to the following points:

- increase in productivity

- capacity expansion

- quality improvement

- faster throughput times

- improvement in working conditions

Panel lines consists of stationary and mobile facilities and have varying degrees of automation and mechanisation:

- Welding gantries for one or two sided butt seam welding

- Turning devices, for example, to turn flat panels

- Gantries for marking and contour cutting

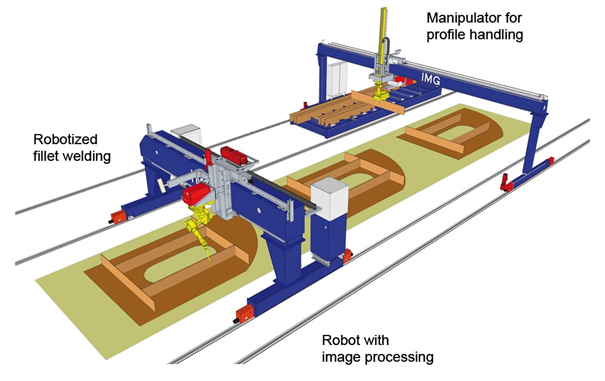

- Profile mounting and tack welding gantries

- Units for fillet seam welding

- Assembly gantries

- Transport systems, e.g. roller conveyors, friction drives, chain conveyors, lifting and transport trucks

- Discharge facilities

- Gantries for welding robots in combination with active 3D image recognition